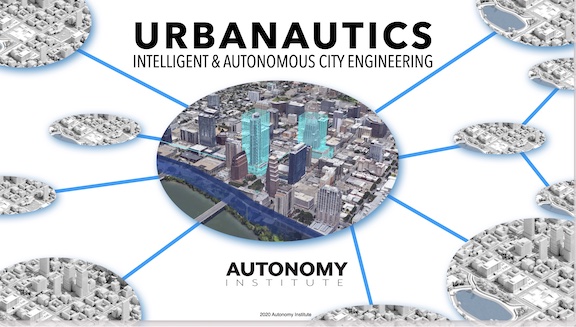

INDUSTRY 4.0 WILL DRIVE JOBS FOR NEXT 100 YEARS

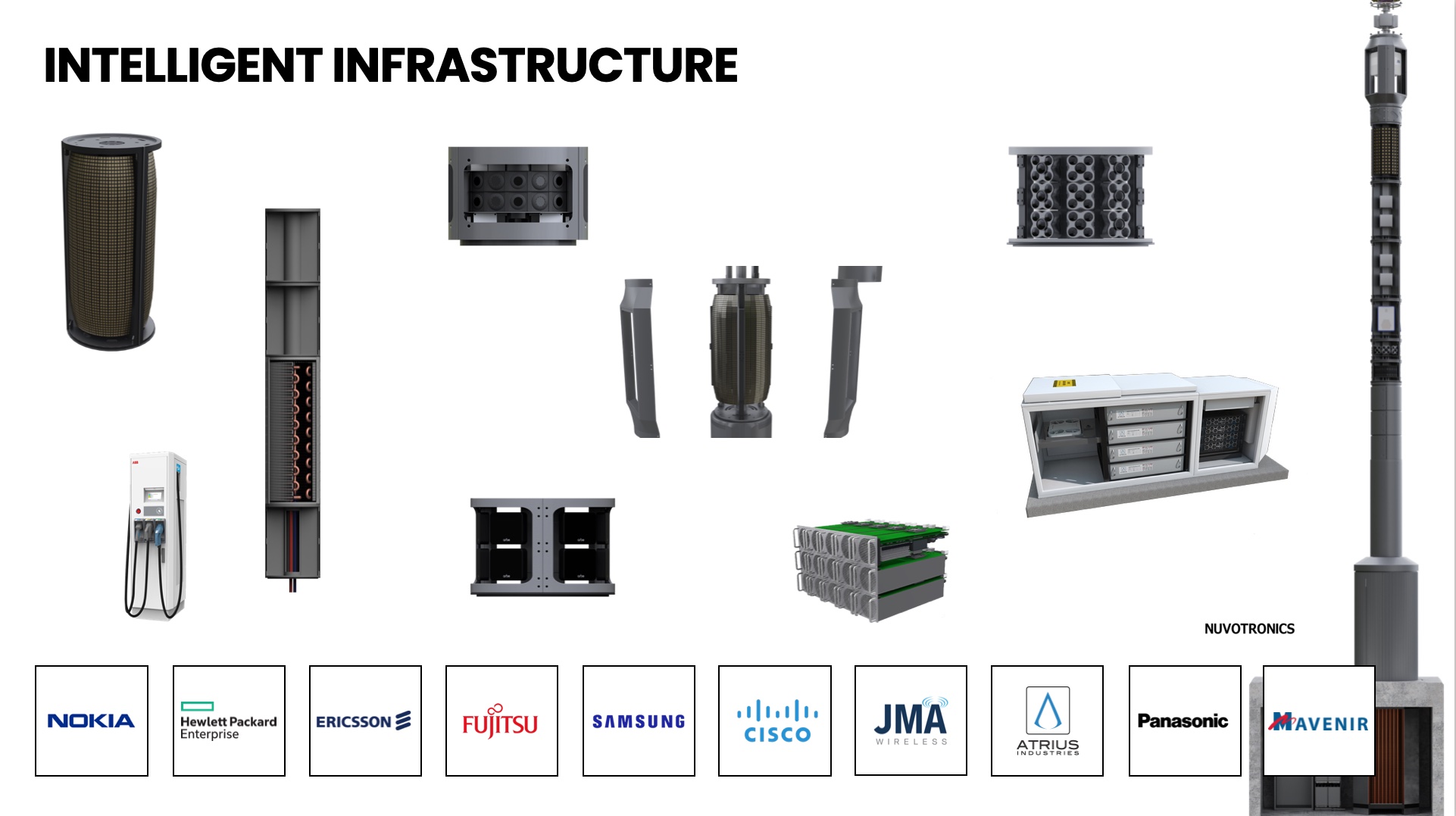

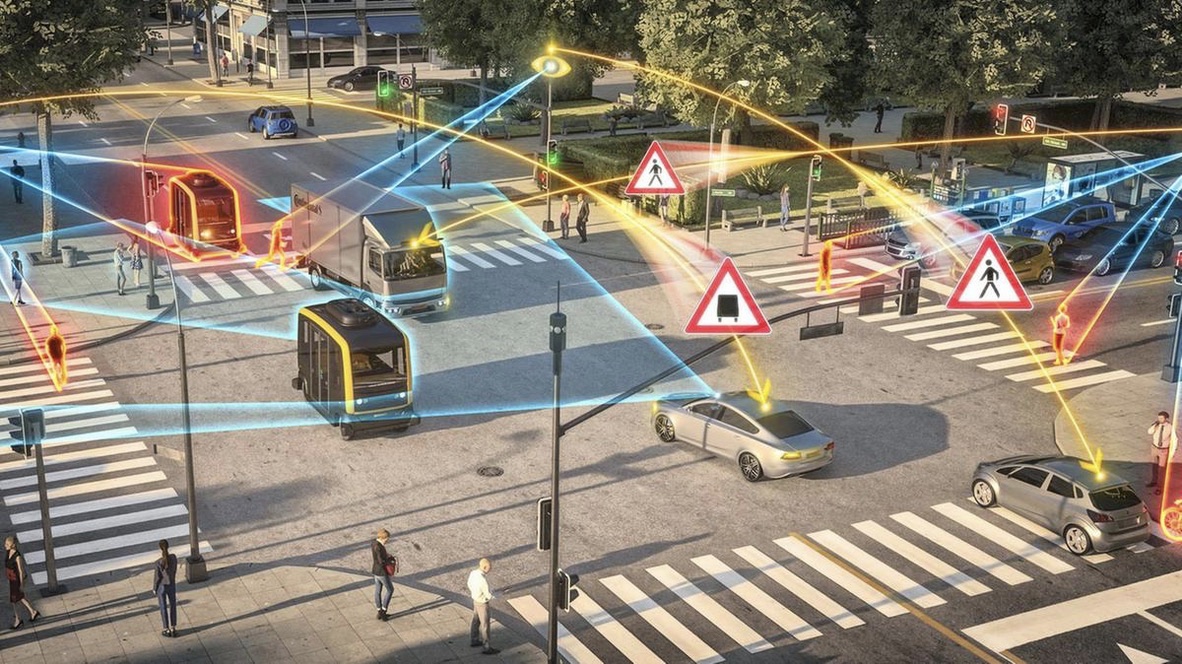

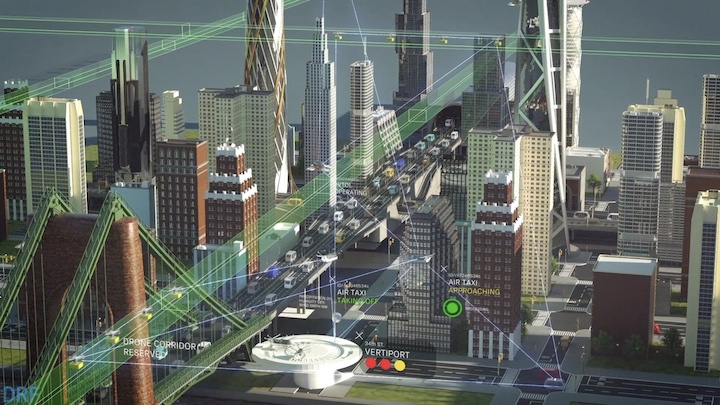

What is the fastest way to create millions of jobs? Invest in the future of the coming transformational Intelligent and Autonomous Infrastructure. Intelligent Infrastructure will Create Millions of Jobs and a Boost in Productivity.

Advances in AI, cognitive computing, and automation mean employers should equip workers with more than technical skills. Skills such as creativity, leadership, and critical thinking will be more important than ever.

“Robots Can Restore Our Humanity” – John Hagel “…an opportunity to redefine work at a very fundamental level. If we do it right, we might actually be able to evolve a form of work that taps into our uniquely human capabilities and restores our humanity. The ultimate paradox is that this technology may become the powerful catalyst that we need to reclaim our humanity.” Chairman John Hagel

How are government and industry leaders preparing?

McKinsey – America’s future of work

A new data visualization maps potential job growth for people and places in America. Explore the data

Deloitte Insights – Closing the employability skills gap

McKinsey & Company – New Jobs of the Future

KPMG – The Future of Work

Do you want to support Intelligent and Autonomous Infrastructure? Request more Information.

INDUSTRY 4.0 CAREERS

Careers of the future: Artificial Intelligence, Urbanautic Engineers, Sensor Technicians, Automotive Engineers, Perception Engineers, PINN Manufacturing, Computer Science, Hardware Design, Embedded Systems, Cybersecurity, Resilient Systems, Wireless Networking, System Operations, Public Policy, Edge Computing, Aerospace Engineers, Radar Design, RF Design, Systems Manufacturing, Data Scientists, PINN Installation, Clean Energy Systems, System Technicians, Urbanautic Policy, Field Service Technician, Field Autonomy Engineer, Autonomous Navigation, Robotics Engineer, Electrical Engineer, Semiconductors, Emergency Response, Mechanical Technicians, Robot Teaming Coordinator, Smart Safety Supervisor, Enterprise Resource Planning, IoT architect, Cyber-physical Systems, and hundreds more.

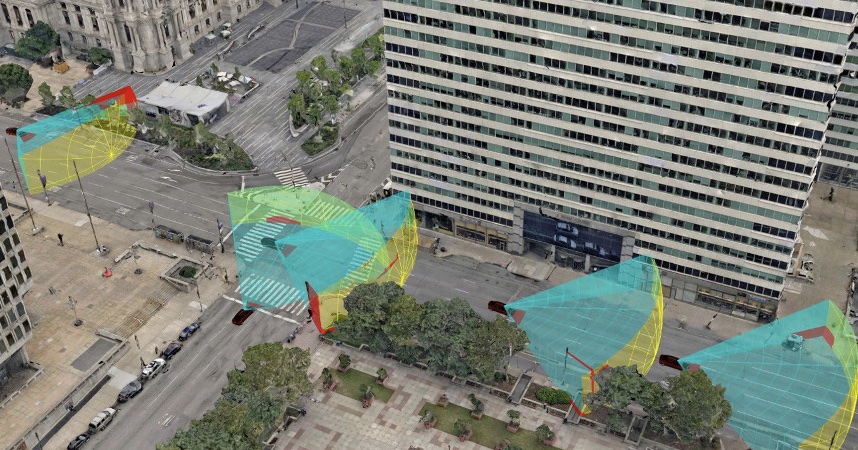

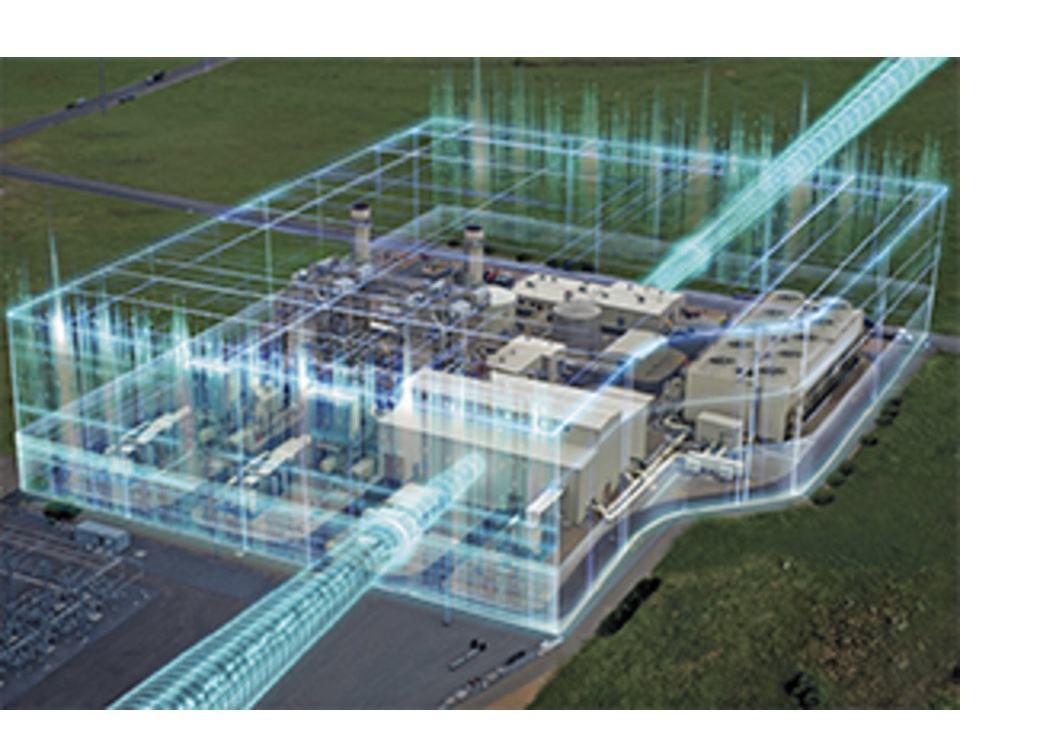

Digital Twin Engineer

A digital twin engineer creates a virtual representation of both the physical elements, as well as the dynamics of how an IoT-connected product operates and interacts. Simply put, a digital twin engineer makes it possible to virtually see inside any physical asset, system, or structure to optimize design, monitor performance, predict maintenance, and improve the overall experience.

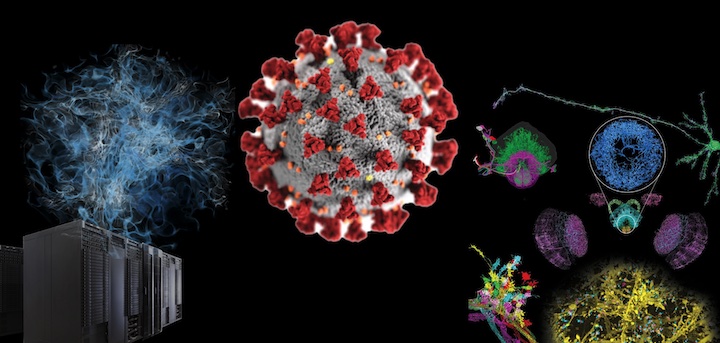

Artificial Intelligence

Data Exchange Engineer

Intelligent Infrastructure Designer

Machines Learning

Vision Zero and Traffic Safety Engineer

Urbanautic Design Engineer

Embedded Electronics

Urbanautic Operations

Silicon Design

PINN Manufacturing

Field Engineer

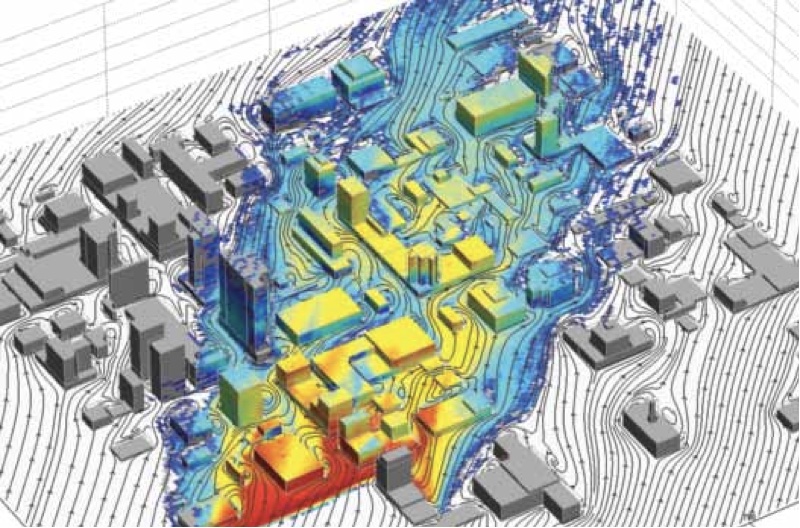

Simulation and Modeling

Urbanautic Mobility Engineer

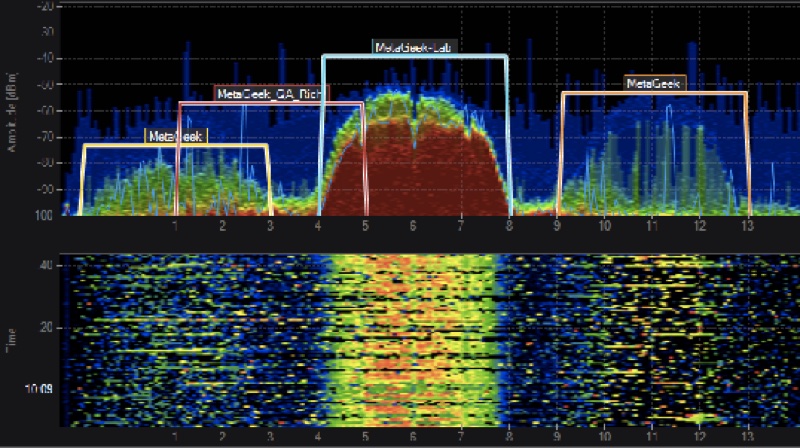

Spectrum Analytics

Biotech Engineer

Data Exchange Engineer

Data Analytics

NextGen Electric Grid

Urbanautic Weather Engineer

Advanced Air Mobility Operations

Satellite Communications Engineer

Mobility 4.0 Engineer

Blockchain Exchanges